English

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| SKU: | |

|---|---|

| Availability: | |

| Quantity: | |

Compression End Mills

We are proud to introduce our Compression End Mills, specially designed to deliver superior cutting performance and high-quality finishes for woodworking and composite material machining. These tools combine advanced materials with innovative design to meet the demands of modern machining applications.

Key Features:

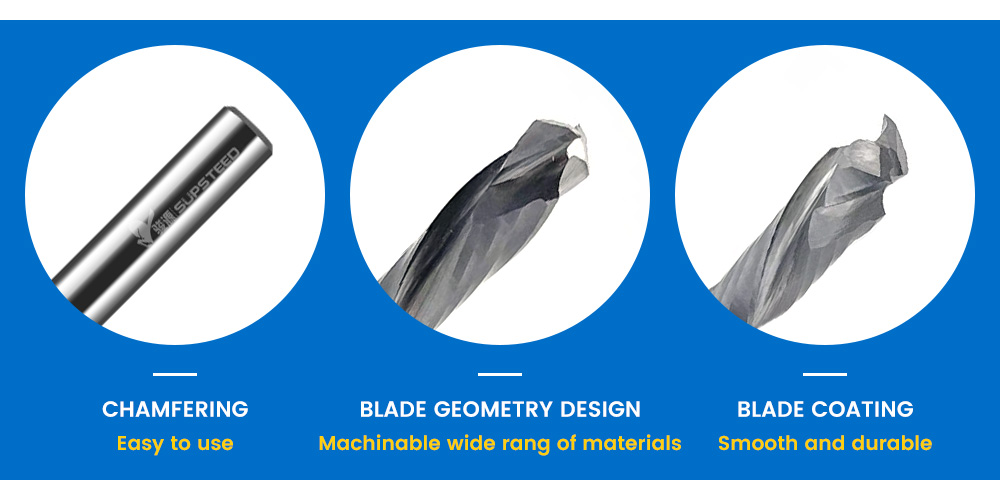

Imported Ultra-Fine Grain Tungsten Carbide:

Our compression end mills are manufactured using premium ultra-fine grain tungsten carbide, ensuring exceptional hardness, durability, and long tool life.

Compression Cutting Design:

The unique up-cut and down-cut flute design compresses material fibers during machining, effectively preventing edge chipping and delamination, and resulting in clean, smooth finishes on both the top and bottom surfaces.

Sharp, Wear-Resistant Cutting Edges:

The cutting edges are precisely ground for sharpness and wear resistance, enabling efficient, burr-free cutting.

Special Coating Treatment:

The surface of the tool is treated with a high-performance coating, enhancing wear resistance and extending the tool's lifespan under challenging machining conditions.

Material Compatibility:

Our Compression End Mills are ideal for machining a variety of materials, including:

Plywood

Laminates

Medium-density fiberboard (MDF)

Composite materials

Hardwoods and softwoods

Advantages:

Clean Finishes: The compression flute design ensures chip-free edges on both sides of the material, eliminating the need for additional finishing.

High Precision: Sharp cutting edges and advanced flute design deliver precise and efficient machining performance.

Durability: Made from ultra-fine grain tungsten carbide and treated with a special coating, these tools offer excellent wear resistance and a long service life.

Versatility: Suitable for both roughing and finishing operations in woodworking and composite material machining.

Show Details

Specitications

| SIZES(D*fL*sD*L) | |||

| D3.175*(17/22)*45L | D8*(17/22/25/32)*60L | D12*42*80L | |

| D4*(17/22)*45L | D8*42*80L | D12*52*100L | |

| D4*25*50L | D10*32*70L | ||

| D4*32*60L | D10*42*75L | ||

| D6*(17/22/25)*50L | D10*42*80L | ||

| D6*32*60L | D10*62*100L | ||

| D6*42*(70/80)*60L | D12*32*70L | ||

Clients Good Feedback

Factory

Service Introduction

Logistics Package

FAQ

Q1: Are you a factory or trading company?

A1: We are professional precision tools manufacturer,have more than 30 years experience in this industry. Welcome to visit us!

Q2: Do you produce special cutting tools?

A2: Yes, we provide OEM/ODM service for customers, just send us your design drawings if you have any customized items need to be made.

Q3: Can the price be reduced for large quantities?

A3: Yes, bigger quantity orders are cheaper.

Q4: When can I get the reply?

A4: We usually reply within 12 hours after we get your inquiry. If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority.

Q5: What is the lead time for mass production?

A5: Generally, It will take 10-15 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q6: Is free shipping available?

A6: We don't offer a free shipping service. But we can have a discount if you buy a large number of products.

Why Choose Us?

Premium Materials: We use premium-grade tungsten carbide to ensure the highest performance and reliability.

Innovative Design: Our compression end mills are engineered for clean cuts, precision, and durability across a range of applications.

Customization Options: We offer tailored solutions to meet your specific machining requirements.

Outstanding Support: Our team is dedicated to providing professional and responsive assistance to meet your needs

Compression End Mills

We are proud to introduce our Compression End Mills, specially designed to deliver superior cutting performance and high-quality finishes for woodworking and composite material machining. These tools combine advanced materials with innovative design to meet the demands of modern machining applications.

Key Features:

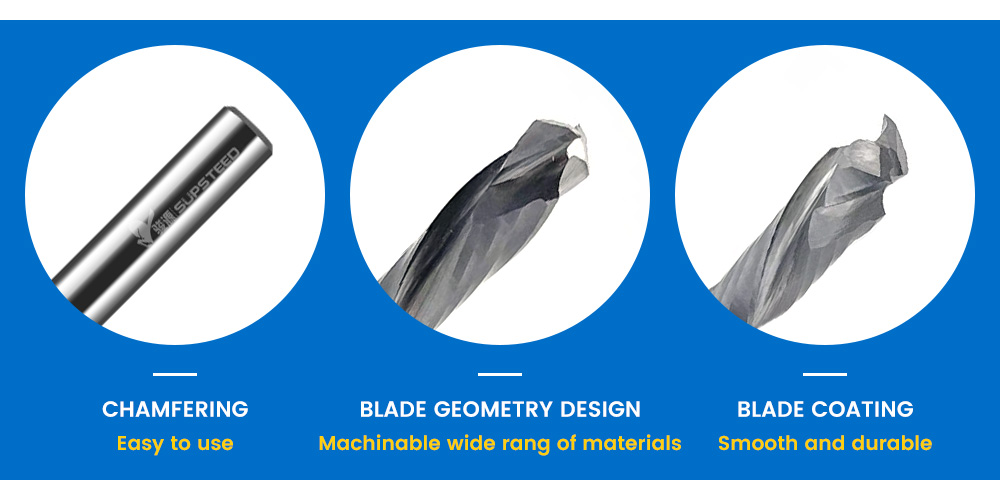

Imported Ultra-Fine Grain Tungsten Carbide:

Our compression end mills are manufactured using premium ultra-fine grain tungsten carbide, ensuring exceptional hardness, durability, and long tool life.

Compression Cutting Design:

The unique up-cut and down-cut flute design compresses material fibers during machining, effectively preventing edge chipping and delamination, and resulting in clean, smooth finishes on both the top and bottom surfaces.

Sharp, Wear-Resistant Cutting Edges:

The cutting edges are precisely ground for sharpness and wear resistance, enabling efficient, burr-free cutting.

Special Coating Treatment:

The surface of the tool is treated with a high-performance coating, enhancing wear resistance and extending the tool's lifespan under challenging machining conditions.

Material Compatibility:

Our Compression End Mills are ideal for machining a variety of materials, including:

Plywood

Laminates

Medium-density fiberboard (MDF)

Composite materials

Hardwoods and softwoods

Advantages:

Clean Finishes: The compression flute design ensures chip-free edges on both sides of the material, eliminating the need for additional finishing.

High Precision: Sharp cutting edges and advanced flute design deliver precise and efficient machining performance.

Durability: Made from ultra-fine grain tungsten carbide and treated with a special coating, these tools offer excellent wear resistance and a long service life.

Versatility: Suitable for both roughing and finishing operations in woodworking and composite material machining.

Show Details

Specitications

| SIZES(D*fL*sD*L) | |||

| D3.175*(17/22)*45L | D8*(17/22/25/32)*60L | D12*42*80L | |

| D4*(17/22)*45L | D8*42*80L | D12*52*100L | |

| D4*25*50L | D10*32*70L | ||

| D4*32*60L | D10*42*75L | ||

| D6*(17/22/25)*50L | D10*42*80L | ||

| D6*32*60L | D10*62*100L | ||

| D6*42*(70/80)*60L | D12*32*70L | ||

Clients Good Feedback

Factory

Service Introduction

Logistics Package

FAQ

Q1: Are you a factory or trading company?

A1: We are professional precision tools manufacturer,have more than 30 years experience in this industry. Welcome to visit us!

Q2: Do you produce special cutting tools?

A2: Yes, we provide OEM/ODM service for customers, just send us your design drawings if you have any customized items need to be made.

Q3: Can the price be reduced for large quantities?

A3: Yes, bigger quantity orders are cheaper.

Q4: When can I get the reply?

A4: We usually reply within 12 hours after we get your inquiry. If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority.

Q5: What is the lead time for mass production?

A5: Generally, It will take 10-15 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q6: Is free shipping available?

A6: We don't offer a free shipping service. But we can have a discount if you buy a large number of products.

Why Choose Us?

Premium Materials: We use premium-grade tungsten carbide to ensure the highest performance and reliability.

Innovative Design: Our compression end mills are engineered for clean cuts, precision, and durability across a range of applications.

Customization Options: We offer tailored solutions to meet your specific machining requirements.

Outstanding Support: Our team is dedicated to providing professional and responsive assistance to meet your needs

content is empty!