English

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| SKU: | |

|---|---|

| Availability: | |

| Quantity: | |

Diamond Coated End Mills

Our company offers high-performance milling cutters featuring advanced CVD (Chemical Vapor Deposition) diamond coatings, expertly engineered for superior performance when machining highly abrasive and challenging materials. These cutting tools are specifically developed to meet the rigorous demands of industries such as aerospace, automotive, electronics, and mold & die manufacturing, where precision, durability, and efficiency are critical.

The CVD diamond coating is deposited in a controlled high-temperature process, forming a thick, uniform, and extremely hard crystalline layer on the tool surface. With a hardness approaching that of natural diamond, this coating delivers outstanding resistance to wear, abrasion, and thermal degradation—significantly extending tool life compared to standard carbide or PVD-coated cutters.

The superior edge retention of CVD diamond-coated cutters ensures consistent cutting performance over extended periods, reducing the frequency of tool changes and minimizing downtime. This translates into higher productivity, improved process stability, and lower cost per part in high-volume production environments.

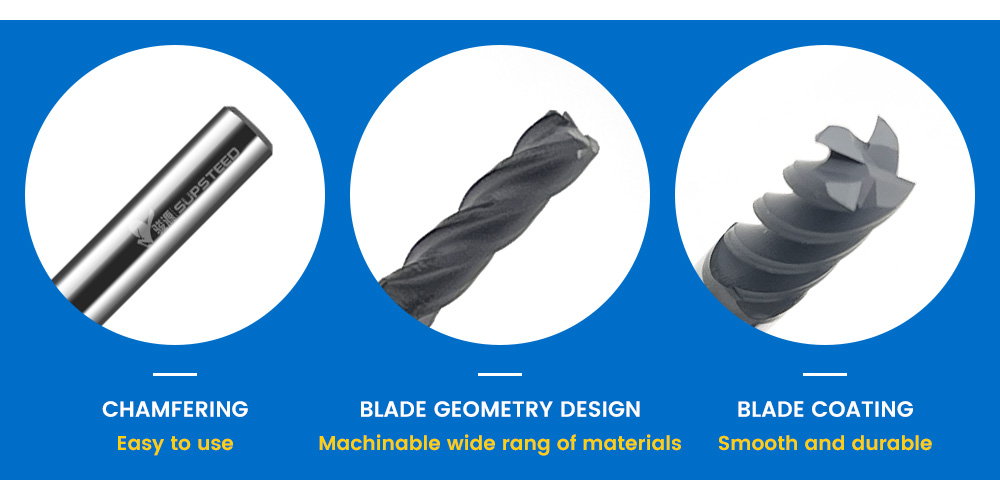

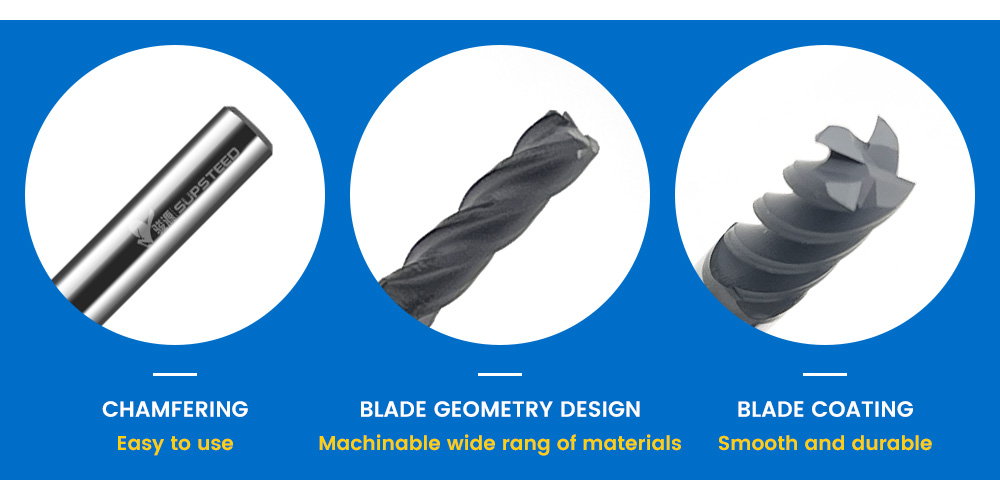

Our cutters are designed with optimized flute geometries and rake angles to facilitate efficient chip removal, reduce cutting forces, and prevent material build-up or delamination—especially important when working with layered composites. The result is clean, precise cuts with excellent dimensional accuracy and superior surface finishes, often eliminating the need for secondary polishing operations.

Available in a range of configurations—including end mills, ball nose cutters, and custom geometries—our CVD diamond-coated milling cutters are compatible with high-speed machining (HSM) centers and CNC systems, ensuring reliable performance in both roughing and finishing stages.

Backed by rigorous quality control and extensive application testing, our CVD diamond-coated milling cutters represent the pinnacle of wear-resistant tooling technology. Choose our solutions for unmatched durability, precision, and efficiency when tackling the most abrasive and demanding materials in modern manufacturing.

Materials Suitable for Machining

Difficult non-metallic materials such as graphite, carbon fiber, high-silicon aluminum, and zirconia.

Show Details

Specitications

| SIZES(D*fL*sD*L) | |

| D1*3*D4*50L | D5*(15/20/25)*D5*(50/75/100)L |

| D1.5*4.5*D4*50L | D6*(18/24/30)*D6*(50/75/100)L |

| D2*6*D4*50L | D8*(24/30/35)*D8*(60/75/100)L |

| D2.5*7.5*D4*50L | D10°(30/45)*D10*(75/100)L |

| D3*9*D4*50L | D12*(30/45)*D12*(75/100)L |

| D3*(9/12/15*D3(50/75/100)L | D14/16/18/20/25*100L |

| D4*(12/16/20)*D4*(50/75/100)L | D6/D8/D10/D12/D14/D16/D18/D20*150L |

Clients Good Feedback

Factory

Service Introduction

Logistics Package

FAQ

Question 1: What is a diamond-coated end mill used for?

• Our diamond-coated end mills are specifically designed for high-efficiency machining of highly abrasive materials such as graphite, carbon fiber-reinforced plastics (CFRP), glass fiber composites (GFRP), ceramics, rubber-modified resins, and high-silicon aluminum alloys. They deliver clean cuts, excellent surface finishes, and extended tool life in demanding applications.

Question 2: How does the CVD diamond coating improve tool performance?

• The Chemical Vapor Deposition (CVD) process applies a thick, uniform layer of synthetic diamond crystals onto the carbide substrate. This coating provides extreme hardness (up to 10,000 HV), superior wear resistance, and excellent thermal conductivity, significantly reducing tool wear and increasing service life—especially in high-volume production environments.

Question 3: Can diamond-coated end mills be used on steel or other ferrous metals?

• No, diamond-coated end mills are **not recommended** for machining ferrous materials such as carbon steel, stainless steel, or cast iron. At high temperatures, the carbon in the diamond coating reacts with iron (a process called graphitization), causing rapid coating breakdown and premature tool failure. These tools are optimized exclusively for non-ferrous and non-metallic composites.

Question 4: What types of flute designs are available for diamond-coated end mills?

• We offer diamond-coated end mills with various flute configurations, including 2-flute, 3-flute, and specialized high-flute-count designs. Two-flute models are ideal for chip clearance in deep slots and soft materials like graphite, while 3-flute versions provide a balance of strength and finish in composites. Custom geometries are also available for specific applications.

Question 5: How do diamond-coated end mills improve surface quality?

• The ultra-smooth, hard diamond surface reduces friction and prevents material adhesion during cutting. This minimizes fiber pull-out, delamination, and burring in composite materials, resulting in superior surface finishes—often eliminating the need for secondary polishing or finishing operations.

Question 6: Are diamond-coated end mills suitable for high-speed machining (HSM)?

• Yes, diamond-coated end mills are exceptionally well-suited for high-speed machining. Their excellent thermal stability allows them to withstand high cutting temperatures without softening or degrading. Combined with balanced geometry, they enable high spindle speeds and feed rates, enhancing productivity and precision in CNC and automated machining systems.

Diamond Coated End Mills

Our company offers high-performance milling cutters featuring advanced CVD (Chemical Vapor Deposition) diamond coatings, expertly engineered for superior performance when machining highly abrasive and challenging materials. These cutting tools are specifically developed to meet the rigorous demands of industries such as aerospace, automotive, electronics, and mold & die manufacturing, where precision, durability, and efficiency are critical.

The CVD diamond coating is deposited in a controlled high-temperature process, forming a thick, uniform, and extremely hard crystalline layer on the tool surface. With a hardness approaching that of natural diamond, this coating delivers outstanding resistance to wear, abrasion, and thermal degradation—significantly extending tool life compared to standard carbide or PVD-coated cutters.

The superior edge retention of CVD diamond-coated cutters ensures consistent cutting performance over extended periods, reducing the frequency of tool changes and minimizing downtime. This translates into higher productivity, improved process stability, and lower cost per part in high-volume production environments.

Our cutters are designed with optimized flute geometries and rake angles to facilitate efficient chip removal, reduce cutting forces, and prevent material build-up or delamination—especially important when working with layered composites. The result is clean, precise cuts with excellent dimensional accuracy and superior surface finishes, often eliminating the need for secondary polishing operations.

Available in a range of configurations—including end mills, ball nose cutters, and custom geometries—our CVD diamond-coated milling cutters are compatible with high-speed machining (HSM) centers and CNC systems, ensuring reliable performance in both roughing and finishing stages.

Backed by rigorous quality control and extensive application testing, our CVD diamond-coated milling cutters represent the pinnacle of wear-resistant tooling technology. Choose our solutions for unmatched durability, precision, and efficiency when tackling the most abrasive and demanding materials in modern manufacturing.

Materials Suitable for Machining

Difficult non-metallic materials such as graphite, carbon fiber, high-silicon aluminum, and zirconia.

Show Details

Specitications

| SIZES(D*fL*sD*L) | |

| D1*3*D4*50L | D5*(15/20/25)*D5*(50/75/100)L |

| D1.5*4.5*D4*50L | D6*(18/24/30)*D6*(50/75/100)L |

| D2*6*D4*50L | D8*(24/30/35)*D8*(60/75/100)L |

| D2.5*7.5*D4*50L | D10°(30/45)*D10*(75/100)L |

| D3*9*D4*50L | D12*(30/45)*D12*(75/100)L |

| D3*(9/12/15*D3(50/75/100)L | D14/16/18/20/25*100L |

| D4*(12/16/20)*D4*(50/75/100)L | D6/D8/D10/D12/D14/D16/D18/D20*150L |

Clients Good Feedback

Factory

Service Introduction

Logistics Package

FAQ

Question 1: What is a diamond-coated end mill used for?

• Our diamond-coated end mills are specifically designed for high-efficiency machining of highly abrasive materials such as graphite, carbon fiber-reinforced plastics (CFRP), glass fiber composites (GFRP), ceramics, rubber-modified resins, and high-silicon aluminum alloys. They deliver clean cuts, excellent surface finishes, and extended tool life in demanding applications.

Question 2: How does the CVD diamond coating improve tool performance?

• The Chemical Vapor Deposition (CVD) process applies a thick, uniform layer of synthetic diamond crystals onto the carbide substrate. This coating provides extreme hardness (up to 10,000 HV), superior wear resistance, and excellent thermal conductivity, significantly reducing tool wear and increasing service life—especially in high-volume production environments.

Question 3: Can diamond-coated end mills be used on steel or other ferrous metals?

• No, diamond-coated end mills are **not recommended** for machining ferrous materials such as carbon steel, stainless steel, or cast iron. At high temperatures, the carbon in the diamond coating reacts with iron (a process called graphitization), causing rapid coating breakdown and premature tool failure. These tools are optimized exclusively for non-ferrous and non-metallic composites.

Question 4: What types of flute designs are available for diamond-coated end mills?

• We offer diamond-coated end mills with various flute configurations, including 2-flute, 3-flute, and specialized high-flute-count designs. Two-flute models are ideal for chip clearance in deep slots and soft materials like graphite, while 3-flute versions provide a balance of strength and finish in composites. Custom geometries are also available for specific applications.

Question 5: How do diamond-coated end mills improve surface quality?

• The ultra-smooth, hard diamond surface reduces friction and prevents material adhesion during cutting. This minimizes fiber pull-out, delamination, and burring in composite materials, resulting in superior surface finishes—often eliminating the need for secondary polishing or finishing operations.

Question 6: Are diamond-coated end mills suitable for high-speed machining (HSM)?

• Yes, diamond-coated end mills are exceptionally well-suited for high-speed machining. Their excellent thermal stability allows them to withstand high cutting temperatures without softening or degrading. Combined with balanced geometry, they enable high spindle speeds and feed rates, enhancing productivity and precision in CNC and automated machining systems.

content is empty!