English

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

T-slot End Mills

Forget ordinary T-slot cutters. SUPSTTED redefines the standard with our NexT-Gen Series T-Slot End Mills, engineered from the substrate up for unparalleled stability and groove perfection in demanding applications. Experience the difference of focused rigidity.

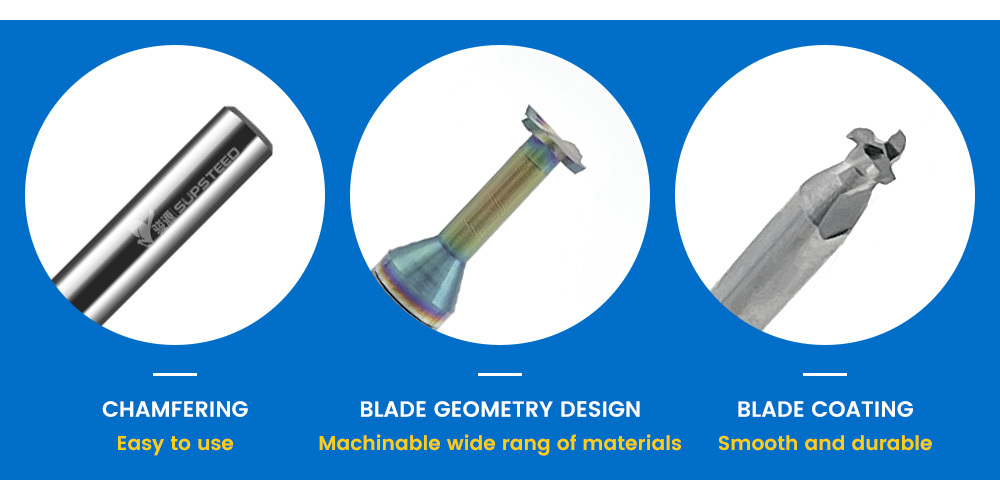

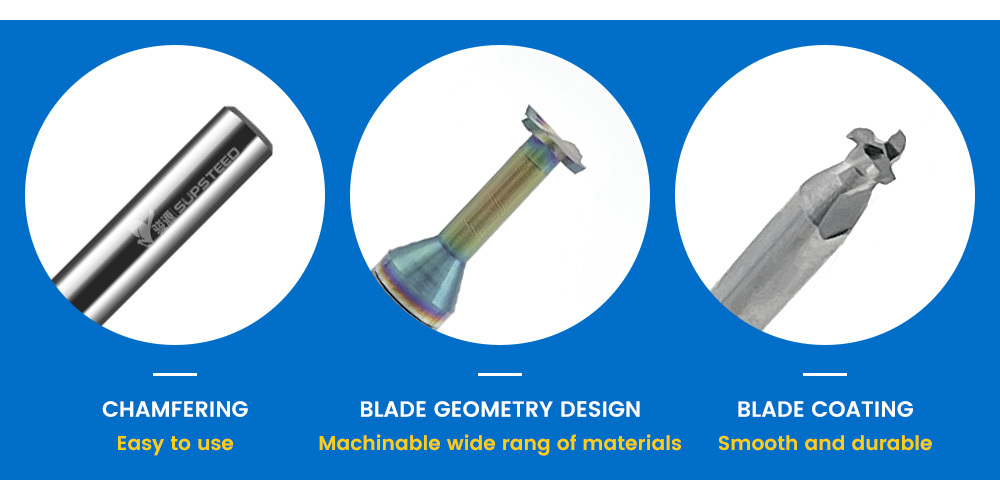

Core Innovation: The Tri-Anchor Flute™ Design

Our proprietary geometry features three strategically reinforced flutes with variable helix angles (38°/42°). This isn't just about chip evacuation; it's about neutralizing harmonic vibration at the critical cutting depth where standard tools deflect. The result? True T-slot walls with near-zero taper and exceptional surface finish (Ra ≤ 0.8 µm achievable), eliminating costly secondary finishing.

Built for Extreme Duty:

Ultra-Dense Carbide Core: Utilizing our Nano-Fused™ substrate with 12% increased density over premium grades, resisting micro-chipping and extending tool life significantly, even in hardened steels (up to 50 HRC) and abrasive composites.

Protekt-Tek™ Coating: A bespoke, multi-layered AlCrSiN nanocomposite coating provides superior heat resistance (1,100°C) and drastically reduced friction. Expect 72% less built-up edge compared to standard TiAlN, maintaining consistent cutting performance.

Precision Ground Relief: Exclusive Micro-Clearance™ secondary relief on the neck minimizes rubbing and heat generation within the slot, critical for maintaining tight tolerances (±0.025mm) over extended runs.

Engineered Performance Benefits:

Zero-Compromise Slot Integrity: Achieve perfect 90-degree shoulders and consistent slot dimensions, run after run.

Predictable Longevity: Dramatically reduced tool wear patterns translate to reliable lifespan estimates and fewer changeovers.

Silent Machining: The Tri-Anchor Flute™ design significantly dampens chatter, enabling smoother, quieter operation at optimal speeds/feeds.

Ideal For: High-precision jigs & fixtures, aerospace structural components, heavy-duty machine beds, and any application demanding absolute fidelity in T-slot geometry and longevity under stress.

Show Details

Specitications

| SIZES(D*fH*sD*L) | |

| D2*(0.5~2.0H)*D4*50L*4F | |

| D3*(0.5~3.0H)*D4*50L*4F | |

| D4*(0.5~5.0H)*D4*50L*4F | |

| D6*(0.5~6.0H)*D6*50L*4F | |

| D8*(0.5~8.0H)*D8*60L*4F | |

| D10*(0.5~10.0H)*D10*60L*4F | |

| D12*(0.5~12.0H)*D12*60L*4F |

Clients Good Feedback

Factory

Service Introduction

Logistics Package

FAQ

Q: What is a T-Slot End Mill, and what is it primarily used for?

A: A T-Slot End Mill is a specialized cutting tool designed explicitly for machining the undercut profile of T-slots into workpieces, typically on milling machines or machining centers. Its unique shape features a cutting profile on the end and sides, combined with a reduced neck diameter below the cutting head. This allows it to plunge down into a pre-cut slot and then move sideways to mill the characteristic "T" shape that accepts T-bolts for clamping.

Q: How do I choose the right size T-Slot End Mill?

A: The critical dimension is the cutter's neck diameter. It must be smaller than the width of the slot created by your initial straight end mill (which forms the top of the "T"). The cutting head diameter determines the width of the undercut (the bottom of the "T"). Select the T-slot cutter based on the desired T-slot size (e.g., for a 1/2" T-slot bolt, you typically need a cutter with a neck diameter slightly less than 1/2" and a cutting head diameter corresponding to the undercut width needed for that bolt).

Q: What are the key specifications I need to know before using a T-Slot End Mill?

A: Essential specifications include:

Shank Diameter: Must match your tool holder (e.g., 1/2", 3/4", 10mm, 12mm).

Cutting Diameter: Determines the width of the undercut.

Neck Diameter: Must be smaller than the slot opening.

Neck Length: Must be longer than the depth of the undercut you need to machine.

Overall Length (OAL): Total tool length.

Flute Count: Common are 3 or 4 flutes. Higher flute counts offer smoother finishes in softer materials.

Material: High-Speed Steel (HSS) for general use, Carbide for harder materials or higher production.

Coating: Optional (e.g., TiN, TiAlN) for increased wear resistance and heat resistance.

Q: What are important operating tips for using T-Slot End Mills?

A:

Pre-Mill the Slot: Always use a standard end mill to machine the straight vertical slot first, slightly wider than the T-slot cutter's neck diameter but narrower than its cutting diameter.

Secure Workholding: Ensure the workpiece is clamped extremely rigidly. Machining T-slots generates significant sideways forces.

Use Proper Feeds/Speeds: Consult manufacturer recommendations. Generally, use lower speeds and feed rates than equivalent end mills due to the interrupted cut and reduced rigidity of the neck. Too high feed rates can cause chatter or breakage.

Climb Milling Preferred: Climb milling (feeding with the cutter rotation) is generally recommended for better surface finish and reduced tool deflection. Conventional milling can pull the cutter into the cut aggressively.

Adequate Lubrication/Coolant: Use flood coolant or mist lubrication to reduce heat, clear chips effectively from the deep slot, and prolong tool life.

Q: Can T-Slot End Mills be used on materials other than aluminum?

A: Yes, T-Slot End Mills are available for machining various materials:

Aluminum: Most common application. Often uses HSS or uncoated carbide with 3 flutes for good chip clearance.

Steel & Stainless Steel: Requires robust carbide cutters, often with 4 flutes and specialized coatings (like TiAlN), run at significantly lower speeds and feeds than aluminum. Rigidity is paramount.

Plastics & Composites: Can be machined effectively with sharp HSS or carbide cutters. Beware of melting; proper chip evacuation is key.

Cast Iron: Carbide cutters are recommended. Dry cutting or using air blast is often suitable.

T-slot End Mills

Forget ordinary T-slot cutters. SUPSTTED redefines the standard with our NexT-Gen Series T-Slot End Mills, engineered from the substrate up for unparalleled stability and groove perfection in demanding applications. Experience the difference of focused rigidity.

Core Innovation: The Tri-Anchor Flute™ Design

Our proprietary geometry features three strategically reinforced flutes with variable helix angles (38°/42°). This isn't just about chip evacuation; it's about neutralizing harmonic vibration at the critical cutting depth where standard tools deflect. The result? True T-slot walls with near-zero taper and exceptional surface finish (Ra ≤ 0.8 µm achievable), eliminating costly secondary finishing.

Built for Extreme Duty:

Ultra-Dense Carbide Core: Utilizing our Nano-Fused™ substrate with 12% increased density over premium grades, resisting micro-chipping and extending tool life significantly, even in hardened steels (up to 50 HRC) and abrasive composites.

Protekt-Tek™ Coating: A bespoke, multi-layered AlCrSiN nanocomposite coating provides superior heat resistance (1,100°C) and drastically reduced friction. Expect 72% less built-up edge compared to standard TiAlN, maintaining consistent cutting performance.

Precision Ground Relief: Exclusive Micro-Clearance™ secondary relief on the neck minimizes rubbing and heat generation within the slot, critical for maintaining tight tolerances (±0.025mm) over extended runs.

Engineered Performance Benefits:

Zero-Compromise Slot Integrity: Achieve perfect 90-degree shoulders and consistent slot dimensions, run after run.

Predictable Longevity: Dramatically reduced tool wear patterns translate to reliable lifespan estimates and fewer changeovers.

Silent Machining: The Tri-Anchor Flute™ design significantly dampens chatter, enabling smoother, quieter operation at optimal speeds/feeds.

Ideal For: High-precision jigs & fixtures, aerospace structural components, heavy-duty machine beds, and any application demanding absolute fidelity in T-slot geometry and longevity under stress.

Show Details

Specitications

| SIZES(D*fH*sD*L) | |

| D2*(0.5~2.0H)*D4*50L*4F | |

| D3*(0.5~3.0H)*D4*50L*4F | |

| D4*(0.5~5.0H)*D4*50L*4F | |

| D6*(0.5~6.0H)*D6*50L*4F | |

| D8*(0.5~8.0H)*D8*60L*4F | |

| D10*(0.5~10.0H)*D10*60L*4F | |

| D12*(0.5~12.0H)*D12*60L*4F |

Clients Good Feedback

Factory

Service Introduction

Logistics Package

FAQ

Q: What is a T-Slot End Mill, and what is it primarily used for?

A: A T-Slot End Mill is a specialized cutting tool designed explicitly for machining the undercut profile of T-slots into workpieces, typically on milling machines or machining centers. Its unique shape features a cutting profile on the end and sides, combined with a reduced neck diameter below the cutting head. This allows it to plunge down into a pre-cut slot and then move sideways to mill the characteristic "T" shape that accepts T-bolts for clamping.

Q: How do I choose the right size T-Slot End Mill?

A: The critical dimension is the cutter's neck diameter. It must be smaller than the width of the slot created by your initial straight end mill (which forms the top of the "T"). The cutting head diameter determines the width of the undercut (the bottom of the "T"). Select the T-slot cutter based on the desired T-slot size (e.g., for a 1/2" T-slot bolt, you typically need a cutter with a neck diameter slightly less than 1/2" and a cutting head diameter corresponding to the undercut width needed for that bolt).

Q: What are the key specifications I need to know before using a T-Slot End Mill?

A: Essential specifications include:

Shank Diameter: Must match your tool holder (e.g., 1/2", 3/4", 10mm, 12mm).

Cutting Diameter: Determines the width of the undercut.

Neck Diameter: Must be smaller than the slot opening.

Neck Length: Must be longer than the depth of the undercut you need to machine.

Overall Length (OAL): Total tool length.

Flute Count: Common are 3 or 4 flutes. Higher flute counts offer smoother finishes in softer materials.

Material: High-Speed Steel (HSS) for general use, Carbide for harder materials or higher production.

Coating: Optional (e.g., TiN, TiAlN) for increased wear resistance and heat resistance.

Q: What are important operating tips for using T-Slot End Mills?

A:

Pre-Mill the Slot: Always use a standard end mill to machine the straight vertical slot first, slightly wider than the T-slot cutter's neck diameter but narrower than its cutting diameter.

Secure Workholding: Ensure the workpiece is clamped extremely rigidly. Machining T-slots generates significant sideways forces.

Use Proper Feeds/Speeds: Consult manufacturer recommendations. Generally, use lower speeds and feed rates than equivalent end mills due to the interrupted cut and reduced rigidity of the neck. Too high feed rates can cause chatter or breakage.

Climb Milling Preferred: Climb milling (feeding with the cutter rotation) is generally recommended for better surface finish and reduced tool deflection. Conventional milling can pull the cutter into the cut aggressively.

Adequate Lubrication/Coolant: Use flood coolant or mist lubrication to reduce heat, clear chips effectively from the deep slot, and prolong tool life.

Q: Can T-Slot End Mills be used on materials other than aluminum?

A: Yes, T-Slot End Mills are available for machining various materials:

Aluminum: Most common application. Often uses HSS or uncoated carbide with 3 flutes for good chip clearance.

Steel & Stainless Steel: Requires robust carbide cutters, often with 4 flutes and specialized coatings (like TiAlN), run at significantly lower speeds and feeds than aluminum. Rigidity is paramount.

Plastics & Composites: Can be machined effectively with sharp HSS or carbide cutters. Beware of melting; proper chip evacuation is key.

Cast Iron: Carbide cutters are recommended. Dry cutting or using air blast is often suitable.

content is empty!