English

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Under Cutting Lollipop End Mills

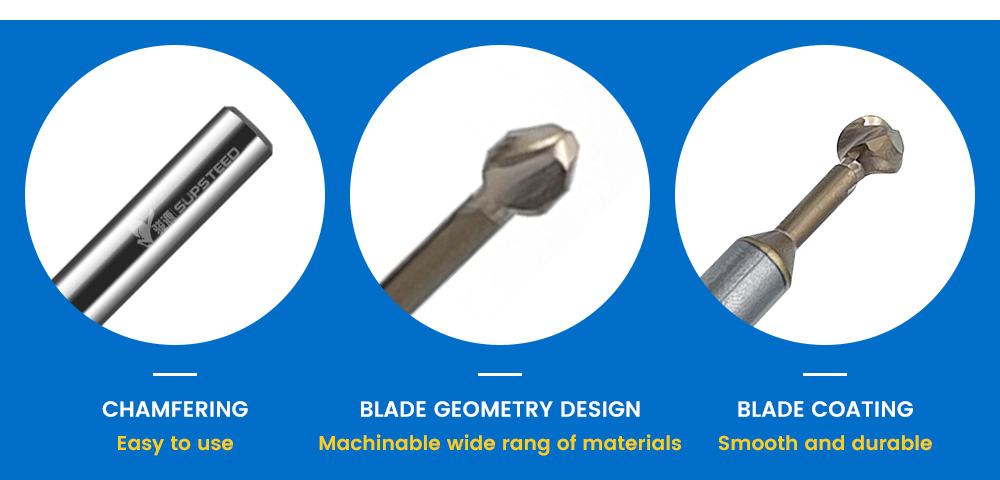

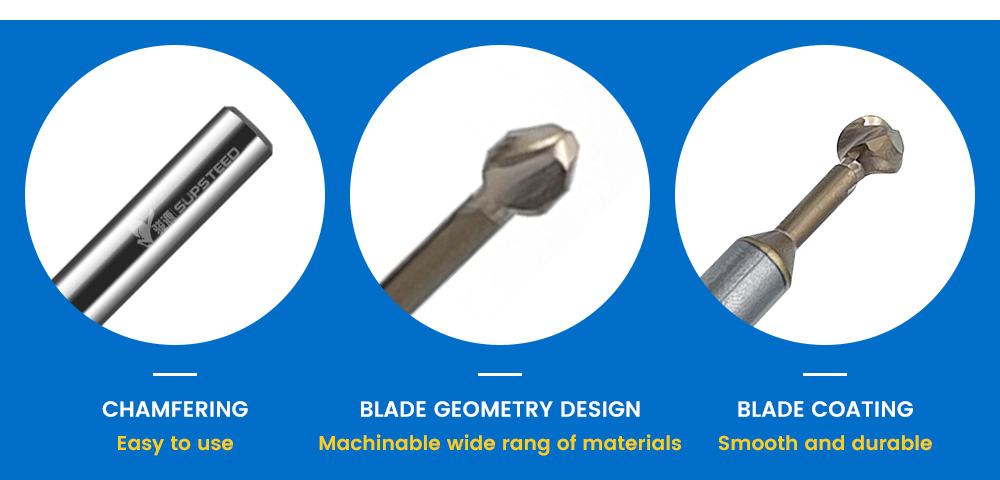

Our company offers high-quality lollipop milling cutters designed for complex contouring, undercutting, and 3D machining. Crafted from premium tungsten steel with high cobalt content, our cutters deliver superior hardness, toughness, and resistance to thermal deformation, ensuring stable performance under demanding cutting conditions. Advanced precision grinding technology guarantees tight tolerances and a mirror-like surface finish on the cutting edges, enhancing cutting accuracy and reducing friction.

Equipped with multi-layer nano-coatings such as AlTiN, TiSiN, or DLC (Diamond-Like Carbon), these cutters exhibit outstanding wear resistance, oxidation resistance, and anti-adhesion properties. This significantly extends tool life, reduces re-sharpening frequency, and maintains sharpness even during prolonged high-speed machining operations.

The unique spherical ball-nose design allows for smooth tool engagement and exceptional access to deep cavities, internal corners, and hard-to-reach areas. This makes them especially effective for machining complex 3D surfaces, molds, dies, impellers, and intricate components in industries such as automotive, aerospace, and precision electronics.

Engineered for versatility, our lollipop cutters perform exceptionally well in both roughing and finishing applications across a wide range of materials—including carbon steel, hardened steels, stainless steel, aluminum alloys, titanium, and composite materials. Optimized flute geometry ensures efficient chip removal, minimizes clogging, and reduces vibration for a smoother cut and improved surface finish.

Available in various diameters, lengths, and shank configurations, our cutters are compatible with CNC machining centers, 5-axis machines, and high-speed spindles. Rigorously tested for balance and concentricity, they ensure reliable, consistent, and efficient performance in high-precision manufacturing environments.

Ideal for mold makers, tool & die shops, and advanced manufacturing facilities, our lollipop milling cutters combine durability, precision, and productivity to help you achieve superior results—every time.

Show Details

Specitications

| SIZES(D*sD*L) | |

| R1*D4*50L*2F | R6*D12*60L*2F |

| R1.5*D4*50L*2F | |

| R2*D4*50L*2F | |

| R2.5*D6*50L*2F | |

| R3*D6*50L*2F | |

| R4*D8*60L*2F | |

| R5*D10*60L*2F | |

Clients Good Feedback

Factory

Service Introduction

Logistics Package

FAQ

Q1: What is a lollipop milling cutter?

A1: A lollipop milling cutter, also known as a ball-end or spherical end mill, features a large hemispherical cutting head mounted on a narrow shank. Its distinctive "lollipop" shape allows for excellent access to deep cavities, undercuts, and complex 3D contours, making it ideal for precision machining in molds, dies, and aerospace components.

Q2: What materials are your lollipop cutters made from?

A2: Our lollipop milling cutters are precision-crafted from high-grade tungsten carbide (also referred to as tungsten steel) with added cobalt for enhanced toughness. This premium substrate provides excellent hardness, wear resistance, and thermal stability, ensuring long tool life and reliable performance under heavy cutting loads.

Q3: What types of coatings do you offer?

A3: We apply advanced multi-layer nano-coatings such as AlTiN (Aluminum Titanium Nitride), TiSiN (Titanium Silicon Nitride), and DLC (Diamond-Like Carbon). These coatings significantly improve surface hardness, reduce friction, resist high-temperature oxidation, and prevent built-up edge, especially when machining sticky materials like aluminum or stainless steel.

Q4: What are the main applications of lollipop cutters?

A4: Lollipop cutters are specially designed for 3D contouring, cavity machining, undercutting, and finishing complex freeform surfaces. They are widely used in mold & die making, automotive tooling, aerospace components, and medical device manufacturing where high surface finish and geometric accuracy are critical.

Q5: Can these cutters be used for both roughing and finishing?

A5: Yes, our lollipop milling cutters are engineered for both roughing and finishing operations. With optimized flute design and sharp cutting edges, they efficiently remove material during roughing while delivering a smooth, high-quality surface finish in the final pass—reducing the need for secondary polishing.

Q6: Are your lollipop cutters compatible with high-speed and 5-axis machining?

A6: Absolutely. Our cutters are manufactured to strict tolerance standards with balanced geometry, making them fully compatible with high-speed machining (HSM) and 5-axis CNC systems. Their design supports smooth toolpath motion and continuous engagement, ideal for dynamic cutting strategies and complex surface milling.

Under Cutting Lollipop End Mills

Our company offers high-quality lollipop milling cutters designed for complex contouring, undercutting, and 3D machining. Crafted from premium tungsten steel with high cobalt content, our cutters deliver superior hardness, toughness, and resistance to thermal deformation, ensuring stable performance under demanding cutting conditions. Advanced precision grinding technology guarantees tight tolerances and a mirror-like surface finish on the cutting edges, enhancing cutting accuracy and reducing friction.

Equipped with multi-layer nano-coatings such as AlTiN, TiSiN, or DLC (Diamond-Like Carbon), these cutters exhibit outstanding wear resistance, oxidation resistance, and anti-adhesion properties. This significantly extends tool life, reduces re-sharpening frequency, and maintains sharpness even during prolonged high-speed machining operations.

The unique spherical ball-nose design allows for smooth tool engagement and exceptional access to deep cavities, internal corners, and hard-to-reach areas. This makes them especially effective for machining complex 3D surfaces, molds, dies, impellers, and intricate components in industries such as automotive, aerospace, and precision electronics.

Engineered for versatility, our lollipop cutters perform exceptionally well in both roughing and finishing applications across a wide range of materials—including carbon steel, hardened steels, stainless steel, aluminum alloys, titanium, and composite materials. Optimized flute geometry ensures efficient chip removal, minimizes clogging, and reduces vibration for a smoother cut and improved surface finish.

Available in various diameters, lengths, and shank configurations, our cutters are compatible with CNC machining centers, 5-axis machines, and high-speed spindles. Rigorously tested for balance and concentricity, they ensure reliable, consistent, and efficient performance in high-precision manufacturing environments.

Ideal for mold makers, tool & die shops, and advanced manufacturing facilities, our lollipop milling cutters combine durability, precision, and productivity to help you achieve superior results—every time.

Show Details

Specitications

| SIZES(D*sD*L) | |

| R1*D4*50L*2F | R6*D12*60L*2F |

| R1.5*D4*50L*2F | |

| R2*D4*50L*2F | |

| R2.5*D6*50L*2F | |

| R3*D6*50L*2F | |

| R4*D8*60L*2F | |

| R5*D10*60L*2F | |

Clients Good Feedback

Factory

Service Introduction

Logistics Package

FAQ

Q1: What is a lollipop milling cutter?

A1: A lollipop milling cutter, also known as a ball-end or spherical end mill, features a large hemispherical cutting head mounted on a narrow shank. Its distinctive "lollipop" shape allows for excellent access to deep cavities, undercuts, and complex 3D contours, making it ideal for precision machining in molds, dies, and aerospace components.

Q2: What materials are your lollipop cutters made from?

A2: Our lollipop milling cutters are precision-crafted from high-grade tungsten carbide (also referred to as tungsten steel) with added cobalt for enhanced toughness. This premium substrate provides excellent hardness, wear resistance, and thermal stability, ensuring long tool life and reliable performance under heavy cutting loads.

Q3: What types of coatings do you offer?

A3: We apply advanced multi-layer nano-coatings such as AlTiN (Aluminum Titanium Nitride), TiSiN (Titanium Silicon Nitride), and DLC (Diamond-Like Carbon). These coatings significantly improve surface hardness, reduce friction, resist high-temperature oxidation, and prevent built-up edge, especially when machining sticky materials like aluminum or stainless steel.

Q4: What are the main applications of lollipop cutters?

A4: Lollipop cutters are specially designed for 3D contouring, cavity machining, undercutting, and finishing complex freeform surfaces. They are widely used in mold & die making, automotive tooling, aerospace components, and medical device manufacturing where high surface finish and geometric accuracy are critical.

Q5: Can these cutters be used for both roughing and finishing?

A5: Yes, our lollipop milling cutters are engineered for both roughing and finishing operations. With optimized flute design and sharp cutting edges, they efficiently remove material during roughing while delivering a smooth, high-quality surface finish in the final pass—reducing the need for secondary polishing.

Q6: Are your lollipop cutters compatible with high-speed and 5-axis machining?

A6: Absolutely. Our cutters are manufactured to strict tolerance standards with balanced geometry, making them fully compatible with high-speed machining (HSM) and 5-axis CNC systems. Their design supports smooth toolpath motion and continuous engagement, ideal for dynamic cutting strategies and complex surface milling.

content is empty!